Keypad Graphics and Surface Treatment

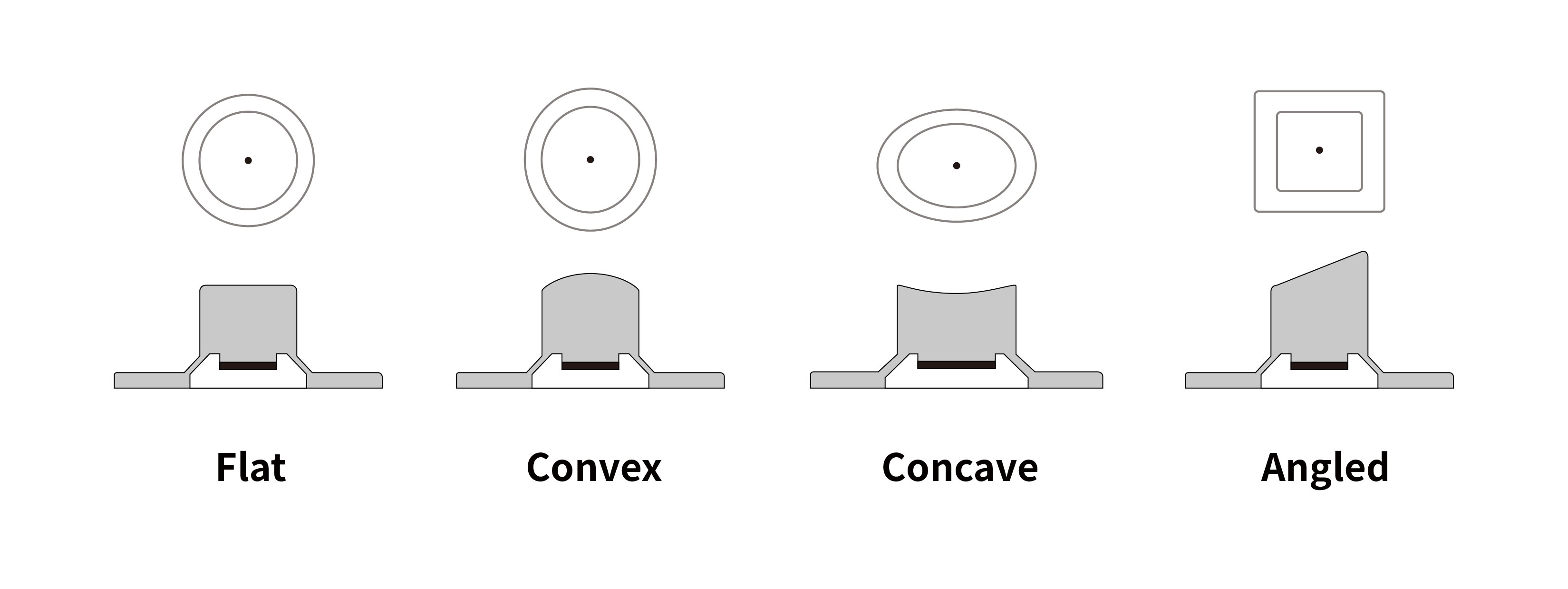

Key Appearance Designs

Screen Printing

Silicone-based printing ink has the characteristics of non-toxicity, high covering property, chemical and weather resistance, good adhesion, good water resistance, etc. Through the screen printing (color separation) process, it can satisfy diverse customer demands for appearance design.

Laser Etching (Light shading and transmission)

By employing laser etching process, silicone keypad surface can be engraved with patterns or symbols required by the customer. In addition, it can present an opaque or transparent effect, and can show a good visual effect when combining with an LED light source.

Spray Coating

The spraying process is often applied in silicone products, which can change the color and light transmission effects of the product according to the design requirements to satisfy market needs. It can also add protective coating onto product surface to achieve dustproof, abrasive resistance and special hand-feel. Common spray coatings are divided into the following categories:

- Silky coating

Silky coating can be applied on surface layer of silicone products to provide a soft feeling and gloss effect as well as to achieve dustproof effect and surface abrasion resistance.

- Polyurethane (PU) coating

PU spraying (coating) on the surface of silicone products can protect the surface printed letter or symbol, increase abrasion and oil resistance, especially suitable for surface coating with matte glaze requirement, and can also increase surface smoothness.

Hard coating

- Silicone colloidal ink for dispersion

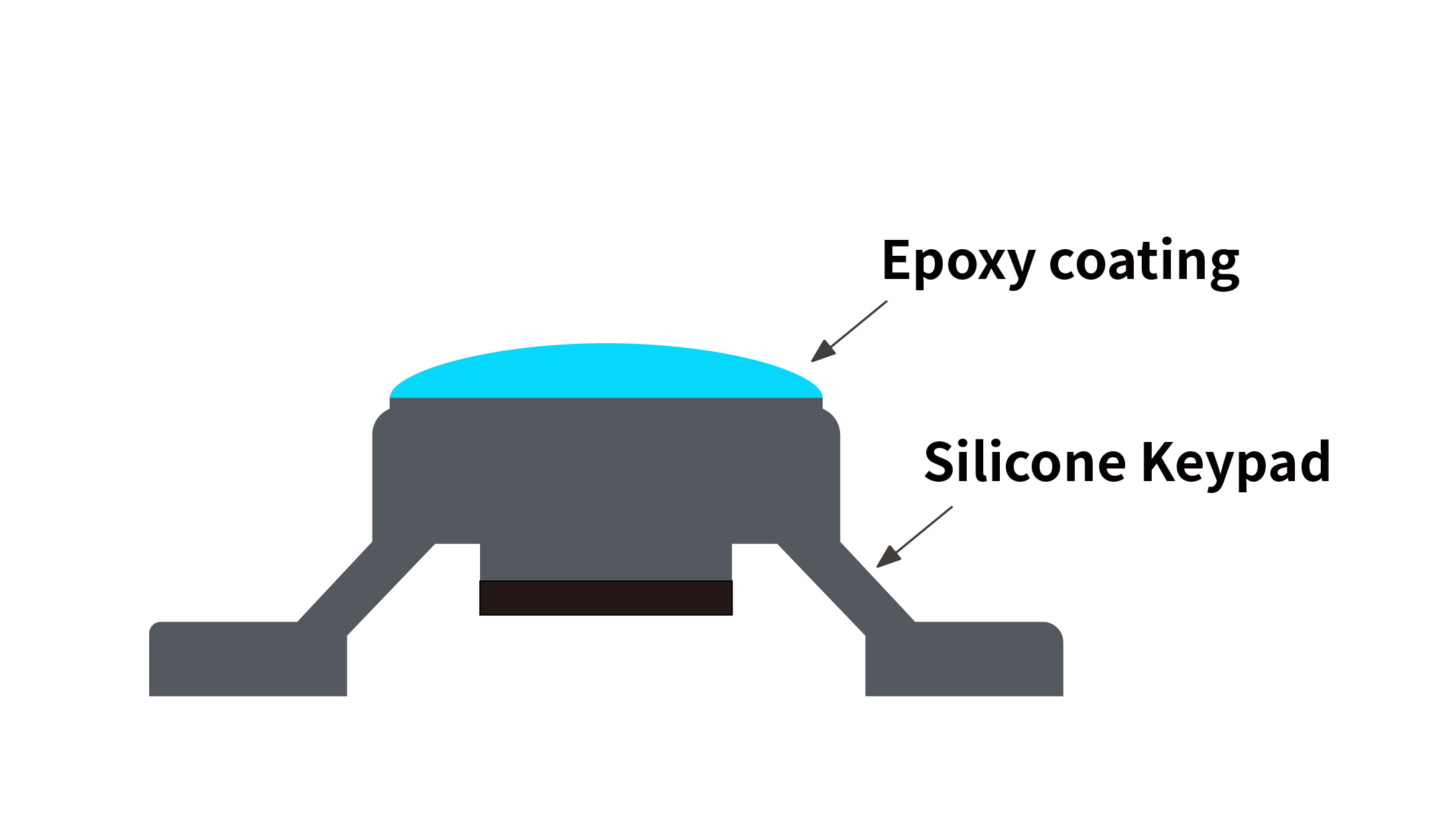

Major function is to increase the effect of recognizing keys on partial or whole area of the key surface such as text, symbols, etc. - Epoxy coating

Silicone keypad surface coated with epoxy resin can only present a bright glossy effect, provide protection and increase product’s service life, and enhance the product texture.

P + R (Plastic & Rubber Keypad)

Design requirements of the surface of plastic key cap can be achieved through screen printing, laser etching processes, and these effects can be combined with silicone keypad through bonding technology.