Thanks to outstanding calendering process capability, General Silicones (GS) are able to offer diverse silicone sheets and films that can be applied in automobiles, industrial electronics, consumer electronics, OA machines, medical markets, etc. GS can produce various silicone calendered sheet and film products according to the raw material properties, specifications, and surface texture (embossment) required by customers. In order to cope with the growth of the optoelectronics industry and the increasing demand for silicone pad and sheet products, our factory is equipped with automated production line for sheet calendering process. From raw material supply, product research and development to design, you will be fully satisfied at our one-stop production and service.

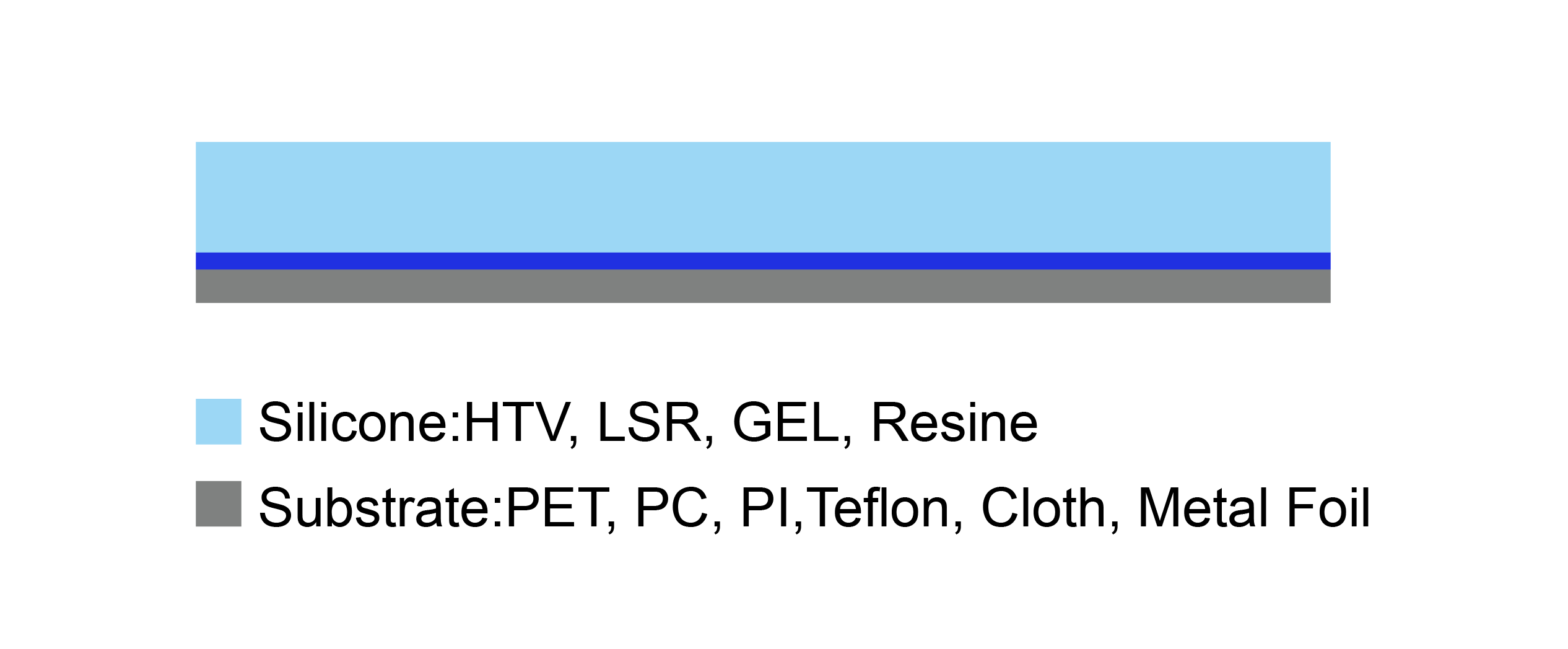

Composite material

Two-layer structure of silicone and substrate are adhered by using primer.

Process capacity:

- Thickness:

Calendering thickness: 0.05 ~ 3 mm

- Width:

Maximum usable width: 1350 mm

- Hardness/Color:

Customized

- Surface treatment:

Gravure coating, spray coating, thin film or embossment wheel transfer

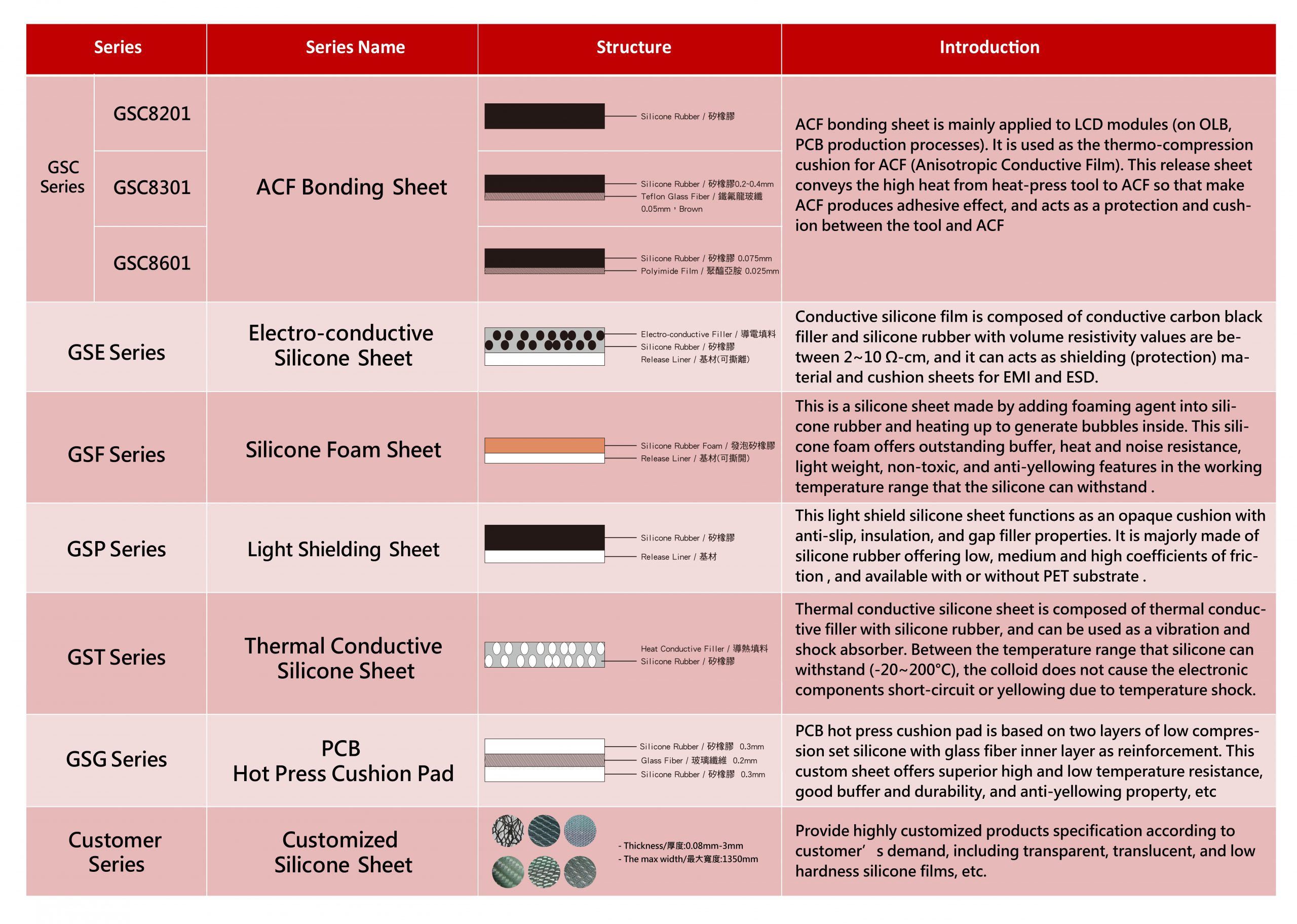

Diverse Standardized Products

General Silicones (GS) offers diverse kinds of standardized products to valued customers based on their demands and market applications. The thickness, hardness, color of these products can be adjusted according to customer needs.